Good User Reputation for China Steel Elbow Pipe Elbow in Combination & Joint Fittings

With our leading technology as well as our spirit of innovation,mutual cooperation, benefits and growth, we will build a prosperous future collectively with your esteemed firm for Good User Reputation for China Steel Elbow Pipe Elbow in Combination & Joint Fittings, In order to expand our international market, we mainly supply our oversea customers Top quality performance products and service.

With our leading technology as well as our spirit of innovation,mutual cooperation, benefits and growth, we will build a prosperous future collectively with your esteemed firm for China Pipe Elbow in Elbow, Pipe Elbow in Combination & Joint Fittings, During in 11 years, We’ve participated in more than 20 exhibitions, obtains the highest praise from each customer. Our company has been devoting that “customer first” and committed to helping customers expand their business, so that they become the Big Boss !

Details

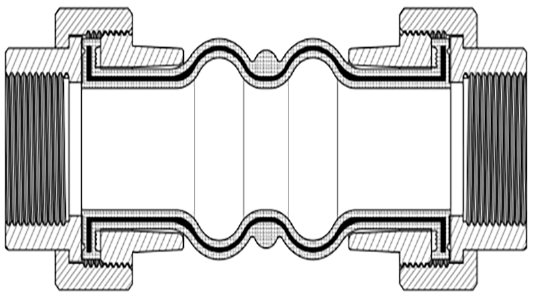

Threaded unions is used When an economical threaded pipe connection is needed, the surface of the union is available both hot-dip galvanizing and electroplating. Both ends provided with a malleable iron union with female thread BS or ANSI.

| Specifications | II | ||

| Working Pressure Mpa (Kgf/Cm2) | 1.6 (16) | ||

| Test Pressure | 2.4Mpa | ||

| Burst Pressure Mpa (Kgf/Cm2) | 4.8 (48) | ||

| Vacuum Kpa (Kgf/Cm2) | 86(660) | ||

| Materials | EPDM/NBR/SBR/NR | ||

| Diameter Range | DN15-DN80 | ||

| Connection Method | THREAD | ||

| Flanges Dimensions | BS, ANSI | ||

| Applicable Medium | Air, compressed air, water, seawater, hot water, oil, acid, alkali etc. | ||

| Loading Port: | Qingdao, China | ||

| Shipment Terms: | FOB, CFR, CIF | ||

| Production Capacity: | 50000 set | ||

| Payment Terms: | L/C, T/T, D/P | ||

| Connection: | THREAD | ||

| Flange Material: | MALLEABLE IRON, DUCTILE IRON | ||

| Period of Delivery | about 21 working days | ||

|

Threaded Union (TU) |

||||||||||||||

|

SIZE |

OAL Length |

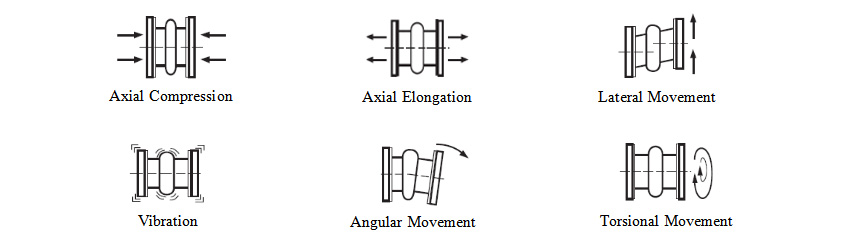

Allowable Movement-1 |

Dimensions |

Operating Conditions |

||||||||||

|

Nominal Diameter |

Neutral OAL |

Min Installed |

Max Installed |

Max Compressed |

Max Extended |

Axial Compression |

Axial Extension |

Lateral Deflection |

Angular Deflection |

OAL Fitting |

OAL Body |

Max w.p. (bar) |

Max Vacuum (in. of Hg)-4 |

|

|

Inch |

mm |

|||||||||||||

|

1/2″ |

15 |

8″ |

7.35″ |

8.12″ |

7.13″ |

8.23″ |

0.87″ |

0.23″ |

+/-0.87″ |

±32.2° |

0.92″ |

6.16″ |

150 |

26″ |

|

3/4″ |

20 |

8“ |

7.35″ |

8.12″ |

7.13″ |

8.23″ |

0.87″ |

0.23″ |

+/-0.87″ |

±32.2° |

1.00″ |

6.00″ |

150 |

26″ |

|

1″ |

25 |

8” |

7.35″ |

8.12″ |

7.13″ |

8.23″ |

0.87″ |

0.23″ |

+/-0.87″ |

±25.3° |

1.25″ |

5.50″ |

150 |

26″ |

|

1-1/4″ |

32 |

8“ |

7.35″ |

8.12″ |

7.13″ |

8.23″ |

0.87″ |

0.23″ |

+/-0.87″ |

±20.7° |

1.25″ |

5.50″ |

150 |

26″ |

|

1-1/2″ |

40 |

8″ |

7.35″ |

8.12″ |

7.13″ |

8.23″ |

0.87″ |

0.23″ |

+/-0.87″ |

±17.5° |

1.35″ |

5.30″ |

150 |

26″ |

|

2″ |

50 |

8″ |

7.35″ |

8.12″ |

7.13″ |

8.23″ |

0.87″ |

0.23″ |

+/-0.87″ |

±13.3° |

1.60″ |

4.80″ |

150 |

26″ |

|

2-1/2″ |

65 |

9.6″ |

8.95″ |

9.72″ |

7.13″ |

8.23″ |

0.87″ |

0.23″ |

+/-0.87″ |

±10.7° |

2.00″ |

5.60″ |

150 |

26″ |

|

3″ |

80 |

9.6″ |

8.95″ |

9.72′ |

7.13″ |

8.23″ |

0.87″ |

0.23″ |

+/-0.87″ |

±8.9° |

2.00″ |

5.60″ |

150 |

26″ |

|

Threaded Union (TU)-Jis Standard |

||||||||||||

|

Nominal Dia |

Nominal |

Allowable Movements (mm) |

Installation Tolerances (MM) |

OAL Fitting (MM) |

OAL Body (MM) |

|||||||

|

Inch |

mm |

Length (MM) |

Lateral Deflection |

Axial Extension |

Axial Compression |

Angular Deflection |

Lateral Deflection |

Axial Extension |

Axial Compression |

Angular Deflection |

||

|

1/2 |

15 |

180 |

15 |

10 |

15 |

15° |

6 |

3 |

6 |

7.5° |

30 |

120 |

|

3/4 |

20 |

180 |

15 |

10 |

15 |

15° |

6 |

3 |

6 |

7.5° |

30 |

120 |

|

1 |

25 |

180 |

15 |

10 |

15 |

15° |

6 |

3 |

6 |

7.5° |

30 |

120 |

|

1 1/4 |

32 |

245 |

20 |

10 |

20 |

20° |

8 |

3 |

6 |

7.5° |

35 |

175 |

|

1 1/2 |

40 |

245 |

20 |

10 |

20 |

20° |

8 |

3 |

6 |

7.5° |

35 |

175 |

|

2 |

50 |

255 |

20 |

10 |

20 |

20° |

8 |

3 |

6 |

7.5° |

40 |

175 |